Not all of the challenge of reducing

transportation-related greenhouse gas (GHG) emissions is found at the

end of automobile tailpipes. The aviation sector currently accounts

for more than ten percent of U.S. transportation-related GHG

emissions. To address this issue, the White House recently announced a

Sustainable Aviation Fuel (SAF) Grand Challenge to generate at least 3

billion gallons of SAFs by 2030 and, by 2050, sufficient SAFs to meet

100 percent of U.S. aviation fuel demand, currently projected to be

around 35 billion gallons annually. Meanwhile, the International Air

Transportation Association (IATA), which represents major global

airlines, has committed to net-zero carbon emissions from global air

transportation by 2050.

Replacing fossil jet fuels with SAFs has been recognized as a crucial

and promising strategy to help the aviation industry meet its

emissions reduction goals, diversify fuel supply, and enhance energy

security. Major U.S. airlines have also pledged to work with the U.S.

federal government and other stakeholders to rapidly advance the

commercialization, deployment, and expansion of SAFs.

The technology needed for SAF production already exists, including

ethanol-to-jet (ETJ) conversion technologies. Producing ethanol from

corn is a mature technology, and life-cycle GHG emissions of corn

ethanol have decreased by roughly a quarter in the past 15 years

, excluding land-use change emissions. Compared to petroleum jet fuel,

SAF produced from today’s corn ethanol also already offers a 15

percent lower carbon intensity. However, to achieve the industry’s

net-zero objectives, additional significant GHG reductions are still

needed.

To assess whether and how the ethanol-to-jet (ETJ) pathway may reach

the net-zero emission target, Argonne scientists performed a

life-cycle analysis (LCA) of corn to ethanol and then to jet fuel,

using the Greenhouse gases, Regulated Emissions, and Energy use in

Technologies (GREET)

® model developed at Argonne. The GREET simulation covers the entire

ETJ pathway, including corn farming, corn ethanol refining, jet fuel

upgrading, and fuel transportation and consumption.

Starting with the current state of the domestic ethanol industry, the

simulation evaluated a range of technologies and GHG management

options applicable to corn farming, ethanol production, and jet

conversion in an attempt to identify key GHG emissions sources in the

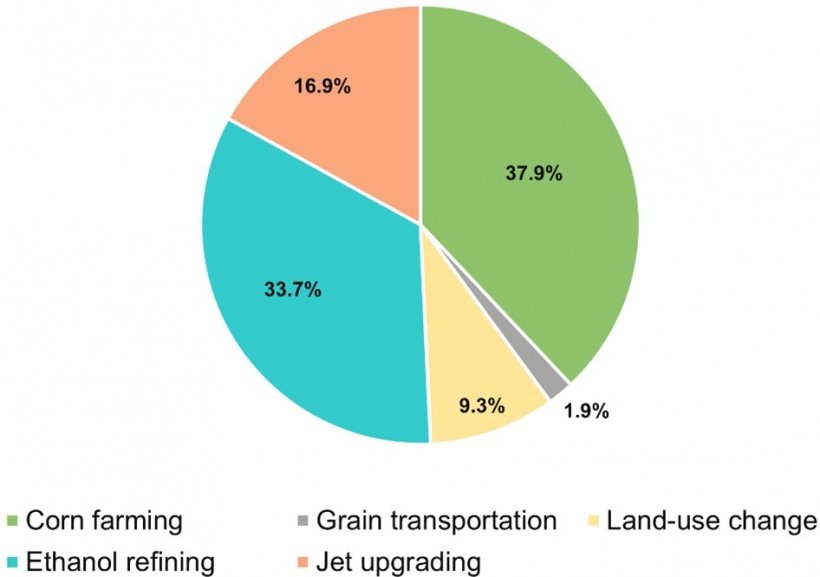

corn-to-ethanol pathway. The simulation revealed ethanol plants and

corn farming to be two major sources of corn ethanol GHG emissions

(Figure 1).

Figure 1. Share of corn ethanol to jet

GHG emissions by source, including both corn-to-ethanol and

ethanol-to-jet processes (the chart does not include 13.4 g CO2e/MJ

jet credits from distillers’ grains with solubles). Image courtesy of

Argonne National Laboratory

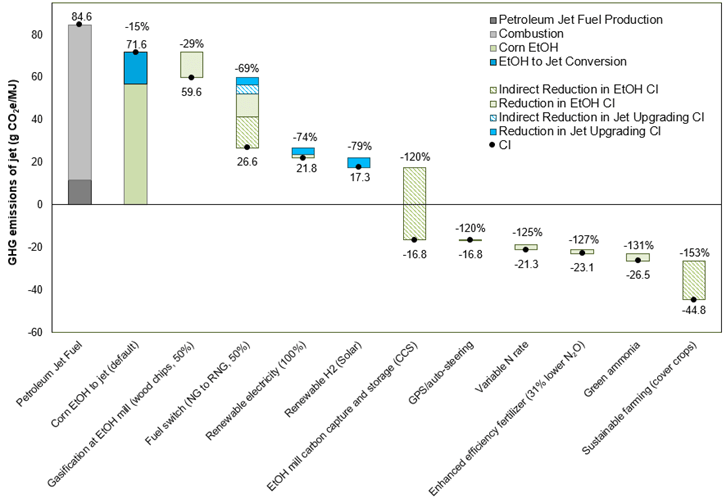

For both ethanol refining and jet upgrading,

energy use (e.g., natural gas for steam generation) helps drive GHG

emissions. For this reason, the analysis evaluated potential options

to displace natural gas (NG). At the ethanol plants, displacing half

of NG with syngas from biomass through gasification may decrease GHG

emissions of ETJ by 12 g CO2e/MJ (Figure 2). Replacing the other half

of NG demand at both ethanol plants and jet upgrading facilities with

renewable natural gas (RNG) from animal wastes could reduce GHG

emissions by 33 g CO2e/MJ on average (Figure 2).

Since CO2 from the corn fermentation unit is the CO2 uptaken from the

air by corn plants in the cornfield, capture and injection of the

fermentation CO2 into geologic formations may generate a significant

GHG credit, causing net GHG emissions of ETJ to be negative (-16.8 g

CO2e/MJ Jet).

In addition to refining, farming is another promising area for jet

fuel decarbonization. The analysis includes several smart farming

practices such as variable nitrogen applications with 4R (right time,

right place, right form, and right rate), and enhanced efficiency

fertilizers help reduce nitrogen fertilizer inputs to corn farms and

reduce N2O emissions from the fertilizers. “Green” ammonia with

renewable electricity and renewable hydrogen further reduce nitrogen

fertilizer GHG footprint. Finally, sustainable farming practices to

increase soil organic carbon contents have the largest GHG reductions

in corn farming. Combining all these measures, GHG emissions of ETJ

can be reduced to –44.8 g CO2e/MJ, which is 153% lower than the

petroleum jet (Figure 2).

Figure 2. Life-cycle GHG emissions (g CO2e/MJ)

of corn to ethanol and then to jet pathway compared to petroleum jet.

Analysis was conducted using the recently released GREET 2021.

Indirect emission credits in hashed bars include avoided emissions

(e.g., avoided methane emissions from animal waste) and carbon

sequestration credits. Image courtesy of Argonne National Laboratory

Overall, the analysis reveals there is

great potential to produce SAFs with potentially zero or

negative GHG emissions, through a combination of cleaner

production technologies and sustainable farming practices. More

R&D, incentives, and coordinated efforts would be needed to

speed up the deployment of these technologies. Argonne’s GREET

model can help guide the biofuel and aviation industry to both

identify carbon reduction opportunities and to move in the right

direction.Thanks to Hui

Xu, Uisung Lee, and Michael Wang at Argonne National Laboratory

for their work as contributing authors on this story.