|

September 19, 2023

By Julian Atchison

Ammonia fuel for glass production

demonstrated in Japan

Asahi Glass Corporation

Earlier this June, AGC announced it had

successfully used 100% ammonia fuel to produce architectural glass

over two days of testing at its Yokohama Technical Center. The project

is an ongoing joint effort, with technical contributions from Taiyo

Nippon Sanso Corporation, the National Institute of Advanced

Industrial Science and Technology & Tohoku University, and support

from government body the New Energy and Industrial Technology

Development Organization (NEDO). AGC confirmed that effects on glass

quality and furnace materials, control of flame temperature, furnace

temperature, and nitrogen oxide (NOx) emissions were all within

acceptable limits.

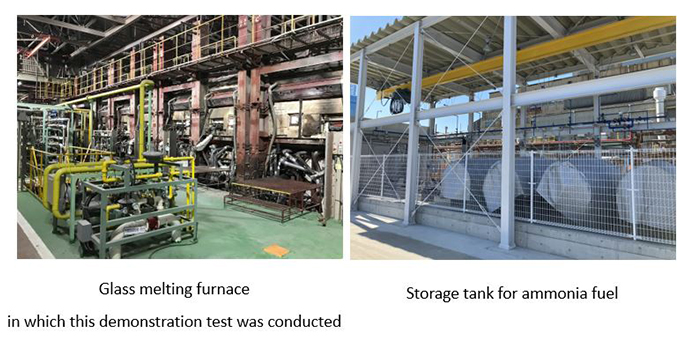

Glass melting furnace & ammonia fuel storage in

Yokohama, where the ammonia fuel demonstration tests took place.

Source: Asahi Glass Corporation.

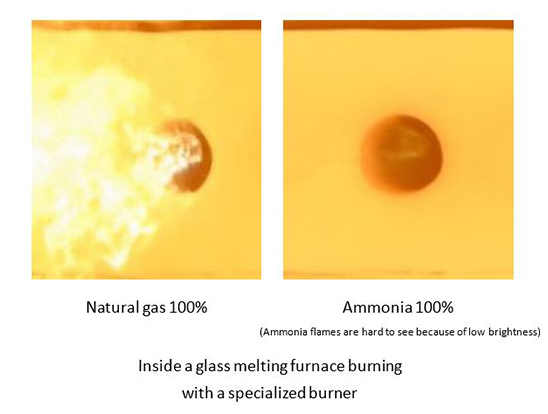

100% gas flame (left) compared to a 100% ammonia flame

(right) inside a glass melting furnace. Source: Asahi Glass

Corporation.

An ammonia-oxygen burner was developed by Taiyo

Nippon Sanso, and designed to “prevent a rapid rise in flame

temperature through multi-stage combustion”. Compared with

conventional fuel combustion (and with tests run under various

conditions), the NOx concentration in the exhaust gas was found to be

below environmental thresholds, while maintaining the required

temperature of the glass melting furnace. From next year, the partners

plan to conduct scaled-up tests and demonstrate the technology at

other AGC sites. From 2026, AGC’s goal is to fully introduce ammonia

combustion technology across its operations. The technology could also

be applied to manufacturing other materials such as steel or aluminium.

…and cement!

The news follows an announcement from Mitsubishi UBE Cement

Corporation in April. MUCC revealed it had begun ammonia co-combustion

tests to produce cement clinker at its Ube Cement Plant (clinker is an

intermediary product leading to Portland cement). To this point, coal

has been the primary fuel in this process, with about one tonne of

carbon dioxide emitted for every tonne of limestone processed. MUCC

reports successful tests, with a goal to increase co-combustion in

stages up to 30%. MUCC predecessor Ube Industries participated in the

Japanese government’s Strategic Innovation Promotion Program (SIP)

from 2014 to 2018.

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

509 995 1879

Cell, Pacific Time Zone.

General office:

509-254

6854

4501 East Trent

Ave.

Spokane, WA 99212

|