|

By

Michael Barnard

November 15,

2023

New ICCT Report On European Trucking

Has Fatal Flaw Favoring Hydrogen

ChatGPT & DALL-E generated panoramic allegorical

image that creatively illustrates the concept of comparing apples and

oranges in the context of energy sources.

The International Council on Clean Transportation

(ICCT) tries to do good and unbiased work. Recently it failed badly,

reporting that hydrogen fuel cell trucks in some categories could

reach parity with diesel in 2030, and have parity or even be cheaper

in 2040 in all categories. Further, it stated that by 2040, for some

use cases it would be competitive with battery electric trucks.

The problem is that the underlying cost of

electricity for hydrogen and for charging batteries was not the same,

not even remotely, despite both scenarios using electricity at

charging or refueling stations. It was different by a factor of three.

A study

by the ICCT from February 2022 by

Yuanrong Zhou and Stephanie Searle found that the price of green

hydrogen manufactured locally at hydrogen refueling stations could

reach €6 per kilogram in 2030. While a conclusion of the report, that

manufacturing hydrogen on site from grid-delivered electricity would

be cheapest, was accurate the assumptions that led to the price point

are unsupportable. The authors used country-specific wind and solar

power purchase agreement prices with limited adders instead of

commercial or industrial grid prices for electricity. As a result,

their price per kWh for electricity was well under €0.10, likely in

the €0.06 – €0.07 range. The report itself excludes the actual numbers

that they used.

Underlying costs

per kilogram of hydrogen from that modeling were used in a just

released ICCT report by two different ICCT researchers, Hussein Basma

and Felipe Rodríguez. That report compared the total

costs of ownership of different energy pathways for trucking in Europe,

with a focus on determining what the most cost effective pathway for

decarbonization would be.

Unsurprisingly,

they found that battery electric trucking was cheapest in all

categories. Very surprisingly, they found that hydrogen fuel cell

trucking was very cheap as well. Hydrogen

Insight’s headline is as

good as it gets given the flaws:

Hydrogen trucks will be more expensive to own and

operate than battery equivalents in Europe until at least 2040: report

But fuel-cell trucks will reach cost parity with diesel

as soon as 2030, says International Council on Clean Transportation

paper

Hydrogen Insight is by far the most balanced of

the hydrogen-specific media outlets, and it is merely reporting what

the report says. Unfortunately, the report is wrong, so the headline

is wrong.

Basma and Rodríguez relied on their colleague’s

cost of hydrogen when manufactured, stored and compressed at the

refueling station for their report. And for battery electric trucks,

they relied on the commercial or industrial average cost of

electricity per kWh, between €0.21 and €0.24.

As a result, their cost of energy for hydrogen at

exactly the same point in the distribution grid using exactly the same

electrons is a third or a quarter of the cost of the energy for

battery electric vehicles.

That something was deeply wrong should have been

clear to Basma, Rodríguez and their reviewers, Chelsea Baldino, Oscar

Delgado, Peter Mock, Tianlin Niu, Rohit Nepali, and Nikita Pavlenko.

The primary interactive diagram that the ICCT created showed that the

cost of energy per kilometer for battery electric was €0.11 compared

to €0.17 for hydrogen in one case in 2030 and dropped to €0.11 to

€0.12 in 2040 in another case, a mere 10% more expensive for the

energy.

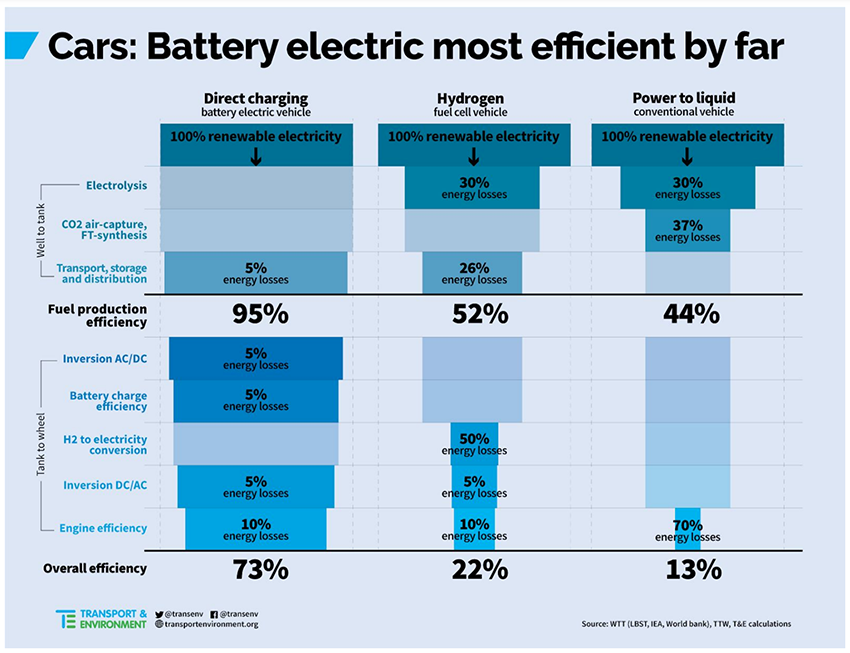

Graphic of electric vehicle vs hydrogen fuel

cell vehicle efficiency courtesy Transport

& Environment

As a reminder, the best case scenario for

manufacturing green hydrogen has an efficiency of roughly 70%. When

100 kWh of electricity is used to turn hydrogen into water, in other

words, only 70 kWh of electricity is embodied in the hydrogen. And

then in the most efficient fuel cell, only 60% of the energy in the

hydrogen is returned as electricity to drive the wheels.

Ignoring all other process losses and capital

costs, that means that at best 42% of the energy in the electricity

could be returned to the wheels. In reality, it’s worse.

The Transport & Environment graphic above shows

the actual efficiency losses for green hydrogen. Even assuming that

the manufacturing it locally at the hydrogen refueling station reduces

the 26% energy losses of transmission, distribution and storage down

to 10%, the best possible case scenario is 27% of the energy returned,

compared to the 73% for battery electric vehicles.

The best possible case using exactly the same

electricity in exactly the same place as the ICCT report does should

show that the cost of energy for a hydrogen fuel cell vehicle is three

times higher than for a battery electric vehicle.

There is literally no way around this fundamental

thermodynamic reality without rewriting the laws of physics. And yet

the ratio of energy costs in the ICCT report just released show energy

costs that are only 1.5 times as high or even 1.1 times as high. This

is a glaringly obvious visual anomaly that the ICCT authors and all of

their reviewers missed. Eyeballing it should have made them realize

that there was a problem.

And to be clear, making storing, compressing and

pumping hydrogen requires much more expensive capital costs at the

refueling station than for battery electric vehicles. Electrolyzers

are very expensive at present, and even if they fall in price

drastically, they will still be more expensive than any component at

an existing truck refueling station. The pumps which will pressurize

the hydrogen to 700 times the pressure of the atmosphere at sea level

are also very expensive. The pumps that drivers use to pump hydrogen

into their trucks are also very expensive (and due to the nature of

the interaction, freeze solid to the vehicle a remarkable percentage

of the time).

Megachargers for electricity power

delivery, by comparison, are much cheaper. And before anyone says, “What

about the grid expansion necessary to delivery the electricity!”,

remember that in both ICCT scenarios, electricity is being delivered

to the refueling station, but in the hydrogen case, three times as

much electricity is being delivered. The cost of beefing up the

distribution grid assuming a hydrogen for energy use case is

significantly higher than for a battery electric use case.

Similarly, leveling electricity demand across a

24/7 cycle to do cost arbitrage and reduce peak demand also favors

battery electric use cases. The capital cost of the electrolyzer

requires high utilization, so it can’t be run at times of low

electricity rates without increasing the cost per kilogram of hydrogen

substantially. As such, the same or larger battery buffer would likely

be required to balance demand with cheapest supply as for the battery

electric trucking solution.

It’s unfortunate that the ICCT has made this

obvious and basic mistake and didn’t catch it. As noted, they try to

do good work, and are not one of the many hydrogen for energy biased

organizations attempting to shoehorn hydrogen into use cases that it

cannot and never will be able to compete in, like trucking. But this

report used electricity a third the price for hydrogen and as a result

gives care and feeding to the biased organizations pushing it, even if

it still found batteries were cheaper.

The ICCT and authors should publicly retract this

report. They should assess all lifecycle trucking reports to see if

the error is pervasive and withdraw any that have also made this

mistake. They should rework their numbers and issue a new and accurate

report. I trust that they will.

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

509 995 1879 Cell, Pacific Time Zone.

General office: 509-254 6854

4501 East Trent Ave.

Spokane, WA 99212

|