|

-+

Return To Main Page

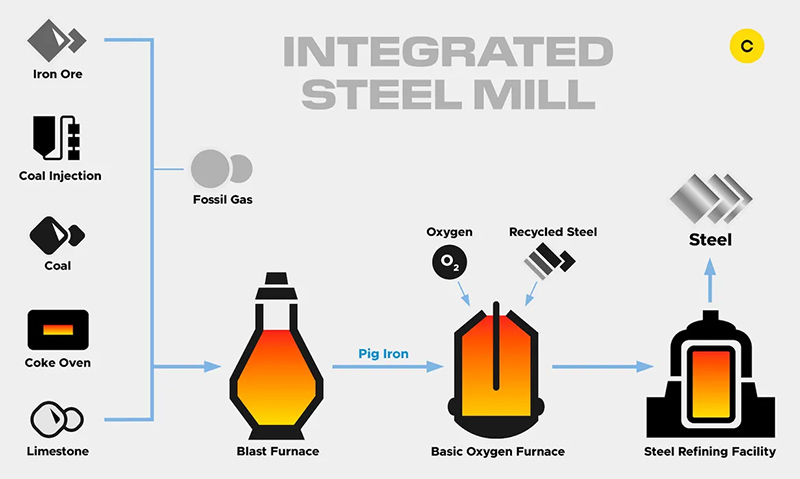

April 10, 2024 How the essential, dirty steel industry is going green Green hydrogen will likely play a key role in decarbonizing steel. Experts discussed the complex transition in Pennsylvania, the birthplace of U.S. steelmaking. PHILADELPHIA — Steel is an essential building block of modern society, used in bridges and buildings, transmission towers, wind turbines, electric cars and so much more. It’s also made using extremely dirty processes. Traditional steelmaking contributes up to 9 percent of global carbon dioxide emissions every year — and produces a toxic soup of pollutants, which harm nearby communities the most. Yet the United States is suddenly on the very cusp of a “green steel” transition. New solutions are emerging that could offer a cleaner path to producing the high-strength metal. Most likely, they’ll involve using hydrogen to process iron ore for steelmaking. On April 5, at this year’s Society of Environmental Journalists conference, I led a panel about the challenges and opportunities of replacing coal-based steel mills with less-polluting methods. The timing couldn’t have been better. The previous week, the Biden administration pledged up to $1 billion to help build two hydrogen-based ironmaking facilities, which will be the first in the United States — and among only a few worldwide. Joining me for the discussion were Edith Abeyta, an artist and community advocate in North Braddock, Pennsylvania, where U.S. Steel operates the 140-year-old Edgar Thomson Plant; Hilary Lewis, the steel director at the advocacy group Industrious Labs; and Chathurika Gamage, a principal in the climate-aligned industries program at RMI, a clean-energy think tank. (Canary Media is an independent affiliate of RMI.) Here are some of the key takeaways from our hour-long conversation, edited for brevity and clarity. 1. Making steel with hydrogen isn’t new — but using “green” H2 isWhen experts talk about green steel, they usually mean ditching the “blast furnace” — the main driver of CO2 emissions from traditional steelmaking. Inside the furnace, iron ore is combined with purified coal (or “coke”) and limestone. A blast of hot air drives chemical reactions that separate oxygen atoms from iron ore, yielding iron. The freed-up oxygen then bonds with carbon monoxide, forming CO2 that’s released into the air. (Iron is later turned into steel in a separate furnace.)

Right now, the leading alternative to the blast furnace is “direct reduced iron,” or DRI. Simply put, the process involves using hydrogen, not coal, to remove oxygen from iron ore. Last month, steelmakers Cleveland-Cliffs and SSAB were each selected to receive up to $500 million to build new DRI facilities in Ohio and Mississippi, respectively. As Gamage pointed out, the technology isn’t new. Around 100 facilities already make iron this way worldwide, including three in the United States. But existing plants use hydrogen derived from fossil gas or coal. Only one commercial operation today — the Hybrit project in Sweden — deploys “green” hydrogen, which is made from renewable electricity and water. Using only renewables-based hydrogen would reduce the overall CO2 emissions from steelmaking by up to 90 percent, Gamage noted. “We know how these things work,” she said of DRI facilities. “Now it’s about getting green hydrogen to these places.” 2. Green steel requires a “daunting,” but not impossible, amount of renewablesSwitching to green hydrogen sounds simple enough. Except that the United States hardly makes any of it right now — and the steel industry needs a lot to replace all that coal. To support one full-scale DRI facility, a company would have to procure around 4 gigawatts of renewable electricity capacity to power 2 gigawatts of electrolyzers, according to RMI. “In terms of numbers and scale, it’s quite daunting,” Gamage said. And that’s just for making iron. A greener steel industry also needs copious amounts of renewables to power the rest of its supply chain. After the iron ore is turned into iron, the material then heads to a second furnace. Traditionally, that’s meant a “basic oxygen furnace” also powered by fossil fuels. But “electric arc furnaces” can do the job using electricity. These facilities blast bolts of electricity to melt down contents into orange liquid, which is then shaped into finished products. If all of today’s coal-based U.S. steel production were to switch to DRI using green hydrogen, as well as adding electric arc furnaces powered by renewables, that would potentially require generating 30 to 35 gigawatts of total renewable energy, said Lewis, citing her group’s “back-of-the-envelope” calculations. On the upside, the U.S. installed about that much new solar energy capacity just last year. But that doesn’t include the facilities that use recycled scrap metal to make what’s called “secondary” steel. The U.S. has about 100 electric arc furnaces for scrap-based steelmaking, and each one of these needs hundreds of megawatts of power to operate — most of which today comes from coal- and gas-fired electrical grids. 3. Steel mills could benefit from H2 hubs, but concerns aboundAmerica’s push for hydrogen-based steelmaking is happening in parallel to another major effort to decarbonize the U.S. economy. Last fall, the U.S. Department of Energy (DOE) picked seven groups to receive up to $7 billion in total federal funding to establish the nation’s first “clean hydrogen hubs.” The projects are meant to dramatically boost investment in low-carbon hydrogen production, while also preparing industries to use hydrogen to reduce their CO2 emissions. Although the groups didn’t single out steelmaking in their proposals, there’s a clear opportunity to link demand from new steel facilities with supply from new hubs, Lewis said. Even so, the hubs aren’t guaranteed to benefit the climate or the communities where they are located, at least not initially. Several projects are expected to include hydrogen derived from fossil gas — which is called “blue” hydrogen when paired with carbon-capture systems. Edith Abeyta, who lives in southwestern Pennsylvania, said she worried that efforts to boost H2 production would further accelerate shale-gas fracking across her home state. “Is this just a way to build more wells, to pollute more communities?” she asked. Abeyta said she’s raised such questions in conversations with public officials, who have vowed to make the hydrogen-hub process more transparent. Still, she questioned the extent to which residents can ultimately influence such negotiations. “The community never gets to say ‘no,’” she added. 4. Details on America’s first “green steel” plants are still fuzzyThe DOE-backed green steel projects by Cleveland-Cliffs and SSAB represent the first clear U.S. attempt to link clean hydrogen with cleaner steelmaking. But the companies and DOE are still in the process of negotiating contracts — meaning that the finer details of the projects aren’t yet decided. “We’re sort of at stage zero with these announcements,” Gamage said. For now, we know that Swedish manufacturer SSAB wants to build a commercial-scale facility in Perry County, Mississippi using Hybrit’s DRI technology, though it didn’t say by when. As part of the initiative, SSAB signed a letter of intent for Hy Stor Energy to supply green hydrogen and renewable energy for the ironmaking facility. Hy Stor Energy plans to use on-site, off-grid renewables to produce hydrogen, which it’ll then store in underground salt caverns in Mississippi. Cleveland-Cliffs, meanwhile, said it will install a “hydrogen-ready” DRI plant at its existing complex in Middletown, Ohio, which could be completed by 2029. The facility will be able to use fossil gas, hydrogen or a mix of both. It’s not yet clear if — or from where — the steelmaker will source green hydrogen for the new project. “That’s something we’re going to be looking at very closely,” Lewis said, adding that it would be “very concerning” from a climate perspective if the steelmaker winds up using hydrogen derived from fossil gas, instead of from renewables. 5. Traditional steelmaking is still making a messAs America’s steelmakers get started on new green facilities, the companies still have significant work to do to curb pollution from the nation’s remaining 13 coal-based blast furnaces — one of which is in Abeyta’s community. U.S. Steel’s Edgar Thomson Plant, like others in the nation, continues to rack up millions of dollars in fines for violating local and federal air quality standards. For decades, residents in the region have grappled with lead and heavy metals pollution, as well as blight from rusty and abandoned equipment at the century-old steelmaking complex. Abeyta described her neighborhood in North Braddock as inclusive and exceptional. “I would say that the majority of the neighbors that I know feel and believe that this is their home. They love it,” she said. At the same time, the area is suffering from decades of disinvestment, which has led to a dearth of schools, grocery stores and other key institutions. “It’s challenging to think about green steel, and what corporations should do, when you don’t have these basic necessities in the place where you live,” she said.

Green Play Ammonia™, Yielder® NFuel Energy. |