|

August 01, 2023

By Kevin Rouwenhorst

Technology status: PEM electrolysis

for renewable ammonia production

Even though alkaline electrolysis remains the

dominant technology for renewable ammonia production, PEM electrolysis

offers substantial benefits like flexible operation and more compact

stacks. By the end of 2023, 36% of installed electrolysis capacity

dedicated to ammonia production will be based on PEM technology.

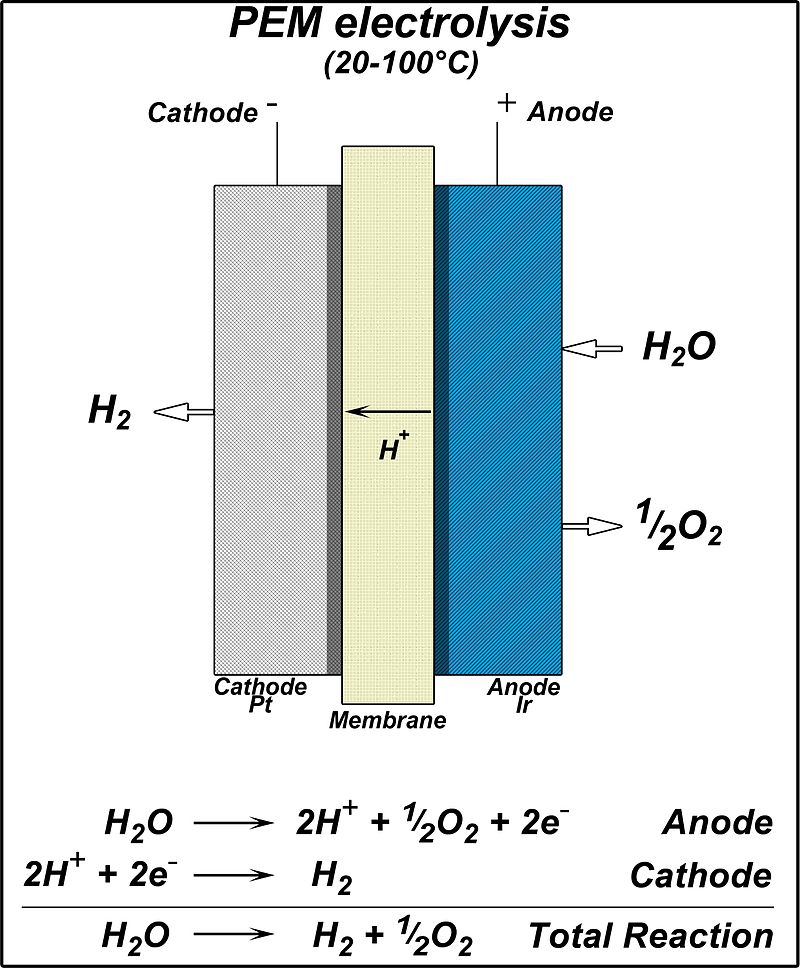

Schematic of a general PEM electrolyser. Source:

Wikipedia.

Within a PEM electrolyzer, oxygen (O2) is

produced from water (H2O) at the anode side via an Iridium oxide (or

Ruthenium oxide) catalyst, producing protons (H+) and electrons (e–)

in the process. The protons pass through the proton exchange membrane

(PEM, Nafion™), and hydrogen (H2) is produced on the cathode side via

a Platinum (or Platinum-Palladium alloy) catalyst.

Recent PEM developments have centered around two issues: i) the

relative scarcity of Iridium, which can be a limiting factor for

scaling up PEM electrolyzer manufacturing, and ii) the membrane

thickness, which limits the efficiency of the PEM electrolyzer.

Iridium loading as determining

factor for scale-up

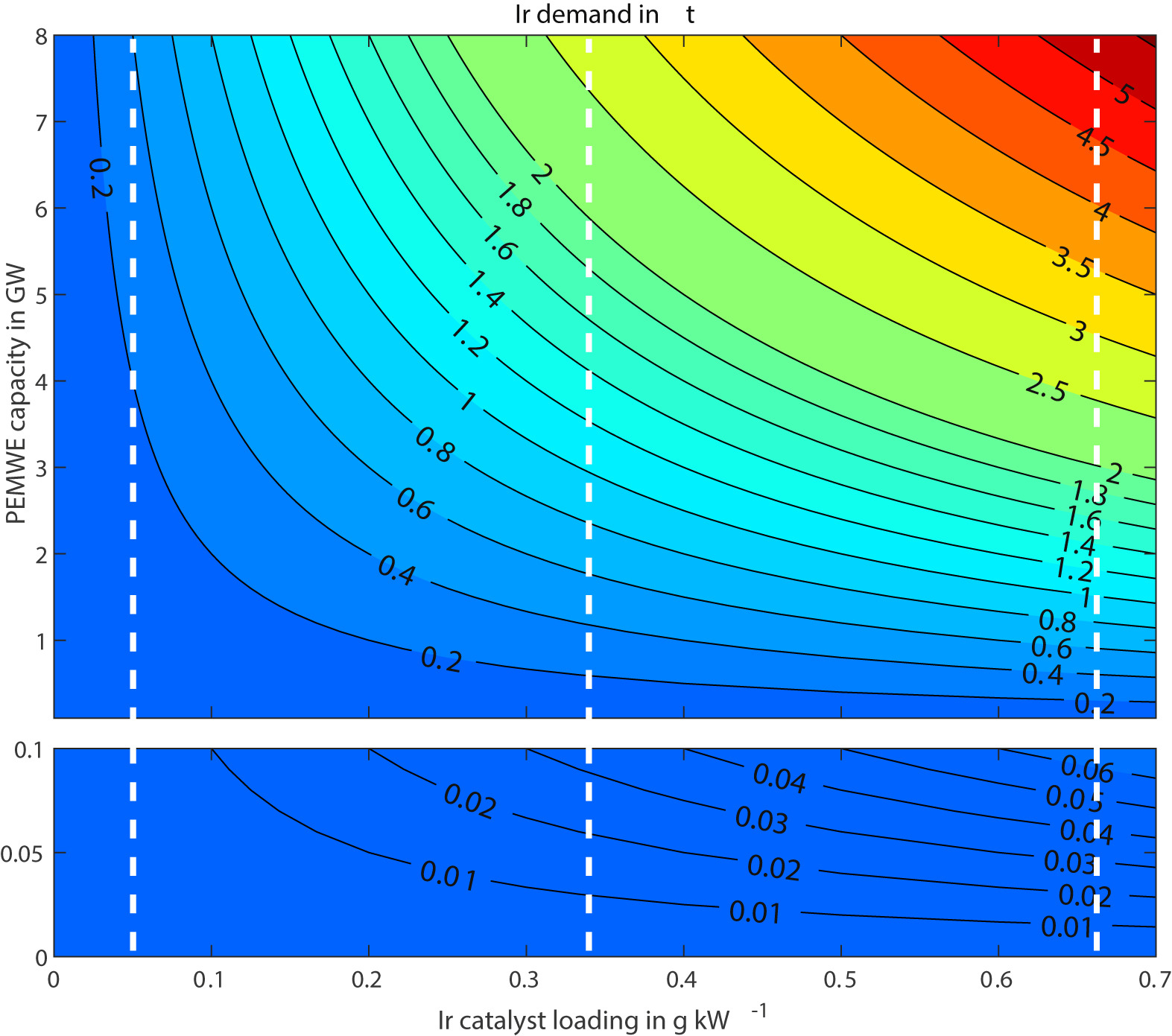

Iridium demand in tonnes, as

function of the PEM electrolysis capacity and Iridium catalyst

loading. From “Is iridium demand a potential bottleneck in the

realization of large-scale PEM water electrolysis?” (International

Journal of Hydrogen Energy, July 2021).

Iridium is one of the scarcest

metals, and is a byproduct of platinum mining. For every tonne of

platinum obtained from ores, about 39 kilograms of iridium is

produced. Iridium is used in LED technologies as well as

electrochemical processes (such as PEM electrolysis). In 2021, the

total global iridium production was just 7.9 tonnes, of which 89% was

produced in South Africa. The remaining production is in Zimbabwe and

Russia.

The global manufacturing capacity for PEM electrolysis is 1.55 GW per

annum, according to the IEA. Minke and co-workers estimated that about

0.67 gram Iridium is currently required per kW PEM electrolyzer. If

all manufacturing capacity for PEM electrolysis is utilized, this

would translate to an Iridium requirement of 1.0 tonne, or 13% of

global Iridium production capacity. Expansion of PEM electrolysis

manufacturing capacity is only possible if Iridium loading is reduced,

without compromising the catalyst activity. In the longer term,

recycling of Iridium from end-of-life PEM electrolysis stacks is

required to minimize additional Iridium requirements.

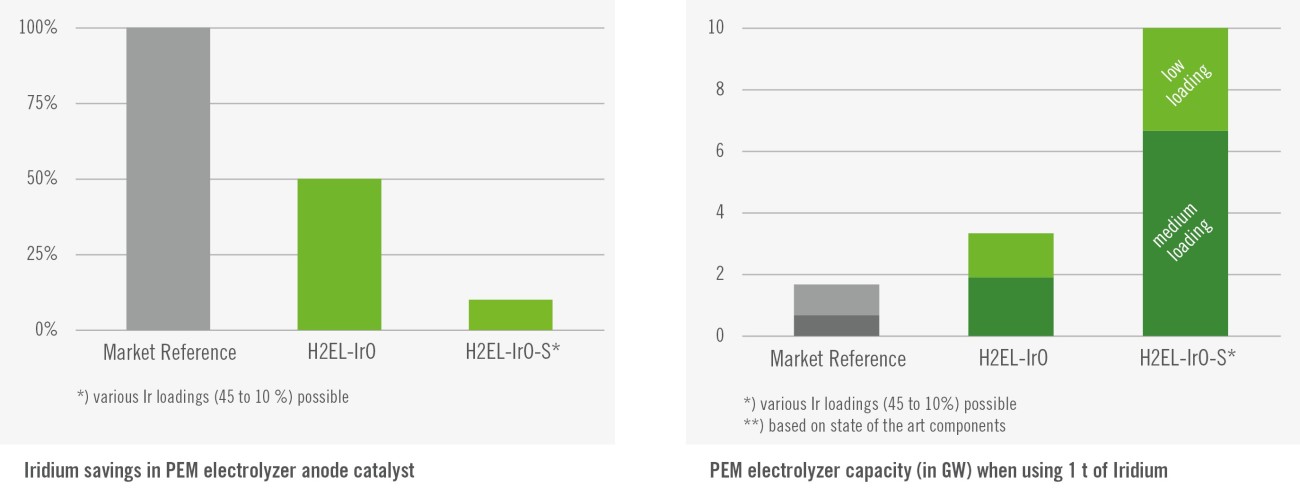

Precious metal company Heraeus

has already commercialized Iridium catalysts (H2EL-IrO) with a reduced

load down to 0.30 gram Iridium per kW. This would reduce the Iridium

requirement to 0.5 tonnes or 6% of global Iridium mining capacity. For

reference, Hereaus estimates that about 1-2 gram Iridium was required

per kW PEM electrolyzer before 2020.

Iridium loading of market references and

Heraeus catalysts. Source: Heraeus.

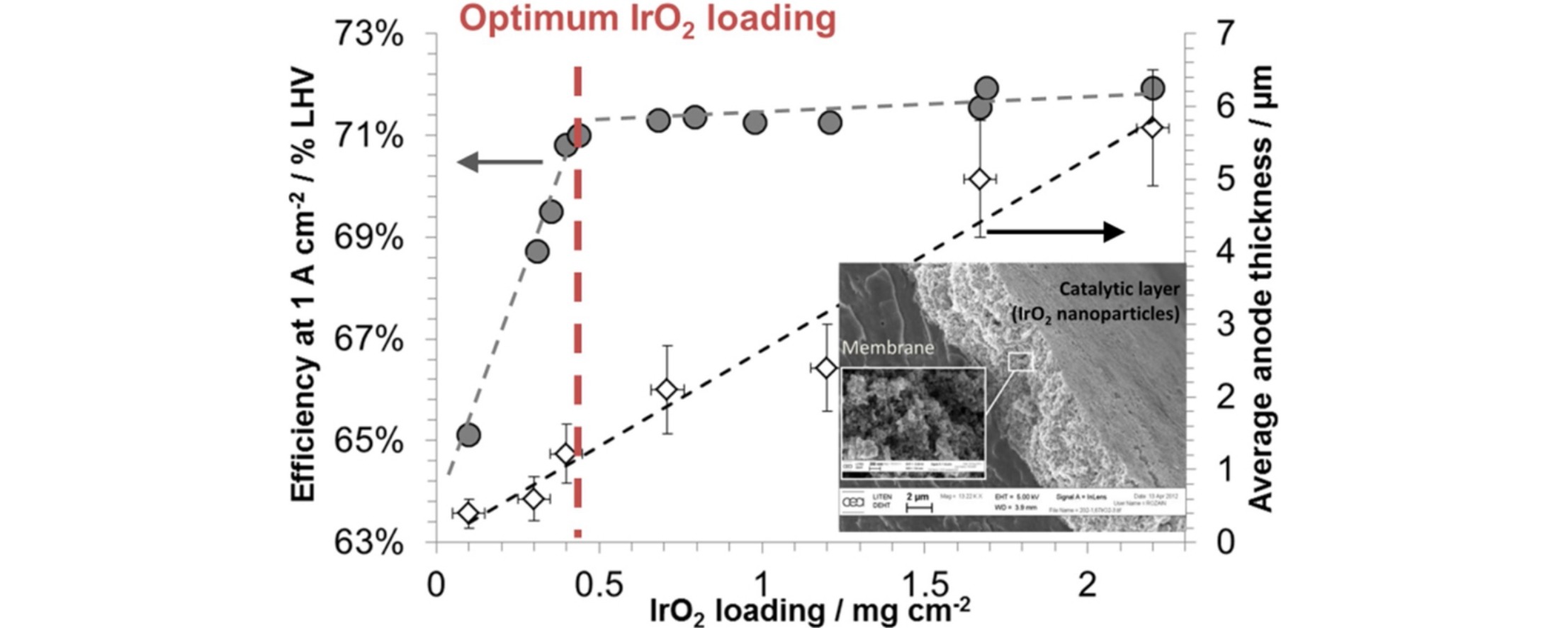

Effect of Iridium loading on PEM

electrolysis performance. 1 mg-IrO2/cm2 is equal to 0.335 g/kW. From

“Influence of iridium oxide loadings on the performance of PEM water

electrolysis cells: Part I–Pure IrO2-based anodes” (Applied Catalysis

B: Environmental, March 2016).

Further reduction in Iridium

loading is actively studied in Universities and research institutes.

Rozain and co-workers found that the performance for PEM electrolysis

was not compromised down to 0.13 gram Iridium per kW. Möckl and

co-workers have tested Iridium catalysts with loadings as low as 0.1

gram iridium per kW in long duration tests. Dutch research institute

TNO claims a 200 times reduction of Iridium loading, while retaining a

third of the performance compared to current PEM electrolyzers. Shi

and co-workers recently demonstrated Ruthenium oxide as an alternative

for Iridium.

Los Angeles-based PEM electrolysis start-up H2U Technologies has

demonstrated a completely Iridium free electrode for its PEM

electrolyzer, based on technology developed at the California

Institute of Technology.

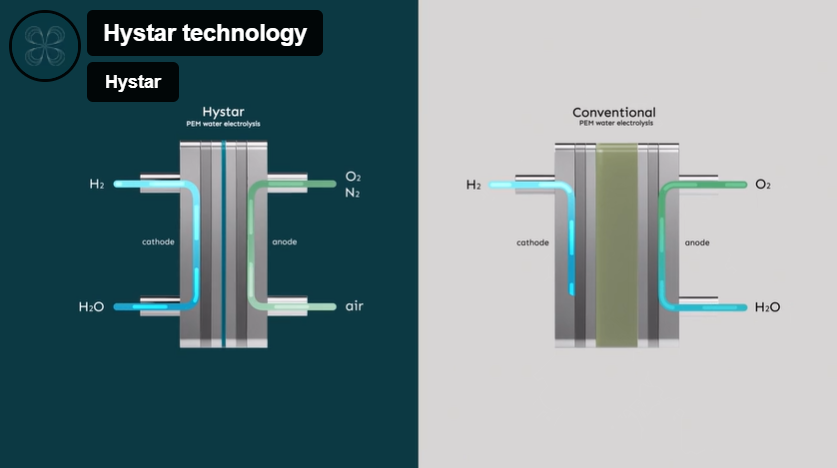

Hystar: reducing the membrane thickness

HyStar is a Norwegian start-up and spinoff from SINTEF, which has

developed a novel PEM electrolysis cell configuration. The performance

of conventional PEM electrolysis is limited due to the thickness of

the proton exchange membrane (about 175 μm), causing resistance to

proton flow and therefore heat losses. However, this thickness is

required to prevent H2 crossover from the cathode to the anode side,

which could result in an explosive mixture for thinner membranes.

Hystar reduces this risk by

introducing humidified air on the anode side, instead of water. This

results in strongly diluted oxygen in a nitrogen atmosphere, reducing

the risk of an explosive mixture. Therefore, Hystar can utilize a

thinner membrane (20 μm). This allows the electrolyzer to operate at

2.5 times the current density compared to a conventional PEM

electrolyzer.

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

www.exactrix.com

509 995 1879 cell, Pacific.

Nathan1@greenplayammonia.com

exactrix@exactrix.com

|