|

13 September 2023

By

Michelle Lewis

Single-blade wind turbine works at

wind speeds of 157 mph

The design takes out expensive components

of the three-blade turbine while also offering lower costs for

installation and servicing.

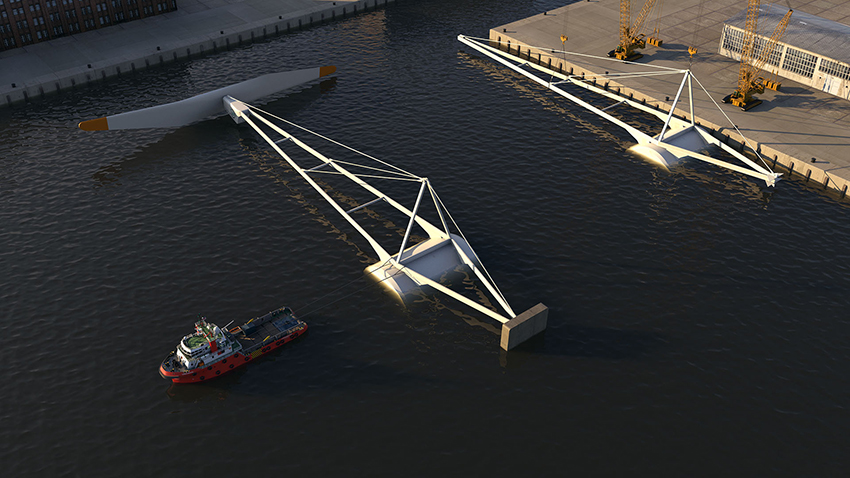

Artist's illustration of the single blade turbine

at work

Netherlands-based TouchWind BV isn't a regular

player in the wind energy industry, looking to make larger wind

turbines to harness more energy. Instead, the company is working to

change what a wind turbine looks like, dumping the three blades in

favor of a single large one.

For years, the wind energy industry has adopted the three-blade model

for its turbines. As the world looks for cleaner sources of energy,

the turbines are getting larger and are also going deeper into the

seas, where winds blow stronger.

The turbine design requires adaptions in these environments, such as

pitch control, to generate maximum power. These additions add to the

cost of the turbine, but when wind speeds exceed design

specifications, the turbine needs to be shut down to avoid damage.

Touchwind's single-blade design solves both these issues in one

stroke.

How does a single-blade turbine work?

The blade is attached to the mast at a slight upward angle. When the

wind speed is low, the mast tilts over and falls into the water but is

prevented from doing so by a dangling buoy.

As the wind speed increases, the spin motion of the single blade

generates lift and pulls the mast upright. The buoy is lifted out of

the water and now serves as a ballast weight to keep the blade from

taking off. Since the blade is no longer at an angle to the wind, it

prevents it from spinning faster. The whole assembly is floating on

the water's surface and anchored to the sea floor.

TouchWind claims that its turbine can function at wind speeds of up to

70 meters per second (157 mph), with the rotor finding its own pitch.

In comparison, a conventional three-blade turbine has to be stopped at

wind speeds exceeding 25 meters per second (56 mph).

The cost reduction

Since the design does not need pitch control systems, which are

expensive components, TouchWind claims that costs of manufacture can

be reduced by as much as 30 percent. The lack of multiple components

also makes it feasible to manufacture the turbine at the harbor,

further reducing the costs of transport.

Fully assembled single blade turbine can be towed

to site of installation - TouchWind

The assembled turbine can simply be towed from

the harbor to the site of installation and become functional after

being anchored to the sea floor. A 656-foot (200 m) blade is estimated

to generate 12 MW of electricity, sufficient to power 15,000

households.

As turbines get larger and farther into the sea, maintaining them is

becoming a herculean task. Weather conditions can get quite rough in

the deep sea, and taller turbines need access via a crane or

helicopter to complete routine maintenance.

In TouchWind's design, the maintenance crew only needs to grab the

cable connecting the buoy and rotor. With the rotor not spinning, the

assembly lies closer to the water surface and can be serviced using a

boat.

The company is currently carrying out field tests of its small-scale

designs in the Netherlands and even received investments from a

Japanese shipping Mitsui OSK Lines. The shipping company also invested

in another wind turbine company, SeaWind, last year.

Details of the commercial rollout of the technology are not available

yet.

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

509 995 1879

Cell, Pacific Time Zone.

General office:

509-254

6854

4501 East Trent

Ave.

Spokane, WA 99212

|